Small Protector, Big Promise: KUOYUH 92 Series Overload Protector Enhances HVAC Transformer Safety

Combining Main and Auxiliary Protection to Safeguard HVAC Systems from Overheating and Short Circuits

Why Does My HVAC System Keep Tripping the Breaker?

Many HVAC users and technicians have encountered this frustrating situation:

The system starts up, but after a short while, the circuit breaker trips, and the air conditioner shuts down completely. Even after resetting the breaker, it trips again soon after. This isn’t just an inconvenience — it’s often a sign of hidden faults within the system. If not resolved early, these issues may worsen over time, potentially leading to transformer burnout, control board damage, or even safety hazards.

So why does your HVAC system keep tripping the breaker?

According to field maintenance data and real-world experience, the most common causes include:

- • Restricted airflow: Dirty filters or blocked ducts increase current draw from the compressor or fan.

- • Poor heat dissipation: Dirty condenser or evaporator coils reduce cooling efficiency, forcing components to run at high temperatures for extended periods.

- • Aging capacitors or sticking contactors: Cause motor startup currents to spike abnormally.

- • Motor short circuits or seized bearings: Create sudden current surges and overloads.

- • Loose or oxidized terminals in the panel: Increase resistance and generate localized heating.

- • Low refrigerant levels: Force the compressor to run longer under heavy load, increasing both current and temperature.

These issues subject the system to sustained overload, placing extreme thermal stress on the control transformer. Although circuit breakers respond to severe current surges, they are not sensitive to gradual, continuous overheating.

The result?

Frequent tripping — but the real source of heat remains unresolved.

Worse still, long-term heat accumulation can cause transformer coil insulation to degrade, resistance to rise, and eventually cause burnout.

Common Faults That Cause Overload or Overcurrent in HVAC Systems

To effectively prevent breaker trips and transformer failure, it’s essential to understand the most likely sources of overload:

| Type | Description |

| Restricted Airflow | Dirty filters or blocked ducts increase load on fans and compressors, raising control circuit current |

| Dirty Coils / Poor Cooling | Dust on the evaporator or condenser traps heat, causing the transformer temperature to rise |

| Aging Capacitors / Sticking Contactors | Unstable current draw and higher control circuit load |

| Motor Short Circuit / Mechanical Jam | Sudden current spikes leading to overload and heat rise |

| Aging Panel or Wiring | Increased contact resistance produces local heating and instability |

| ALow Refrigerant | Prolonged high-load operation keeps control circuits hot for extended periods |

These “hidden overloads” are extremely common in HVAC systems. Without timely detection, the transformer will continue heating silently — until the coil burns out.

Solution: KUOYUH 92 Series Overload Protector

The most effective way to prevent transformer damage is to install a thermal overload protector inside the transformer. This device monitors coil temperature and interrupts power before damage occurs.

The KUOYUH 92 Series is purpose-built for transformers, motors, and power supplies, offering:

- Thermal + overcurrent dual sensing — opens the circuit when the coil temperature exceeds the set threshold (e.g. 120°C).

- Manual reset — After the fault is cleared and the temperature is restored, it must be manually reset, and the system can be safely restarted.

- Multiple ratings available — 1A to 20A current, temperature options.

- Certified quality — UL, TUV, and RoHS compliant for international markets.

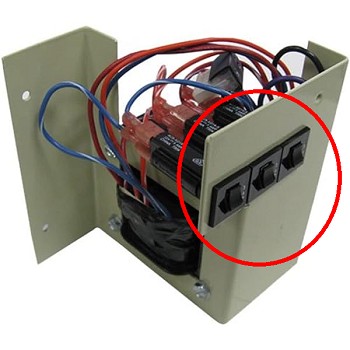

(The circled part in the picture is the installation position of the KUOYUH 92 series circuit breaker. One HVAC can be equipped with multiple circuit breakers for protection.)

Protection in Real-World Scenarios

| Fault Scenario | KUOYUH 92 Protection |

| Airflow blockage/poor cooling | Detects coil temperature rise, cuts off early to prevent heat buildup |

| Capacitor aging/contactor sticking | Monitors heat from overcurrent, trips proactively |

| Motor jam / short circuit | Senses excessive heat, isolates transformer from overload |

| Continuous heavy load | Opens the circuit at the temperature threshold, preventing gradual burnout |

Case Study: Prevention Is Better Than Repair

A commercial HVAC system suffers reduced cooling efficiency due to a dirty condenser.

The compressor runs under heavy load, increasing the control circuit current. The transformer coil temperature gradually approaches its critical limit.

- • Without protection: The coil overheats, insulation breaks down, and the transformer burns out.

- • With KUOYUH 92: The protector trips before reaching 120°C, cutting power to prevent damage.

After maintenance (cleaning the condenser), the temperature dropped, and the protector was manually reset. The system resumes operation — no replacement needed.

Preventing damage upfront saves time and cost compared to post-failure repairs.

Maintenance & Best Practices for Effective Protection

- • Regularly clean air filters and ducts to maintain airflow.

- • Clean coils to ensure efficient heat dissipation.

- • Check motor current and capacitor health.

- • Inspect the distribution panel and connections.

- • Select the correct KUOYUH 92 specifications:

- Current: 10–20% higher than the transformer’s normal load.

- Temperature: 100°C, 120°C, or 130°C depending on design.

Frequently Asked Questions (FAQ)

Q1: Why install KUOYUH 92 inside the transformer?

A: External breakers respond to overall circuit current, but not internal heat. KUOYUH 92 directly senses the heat source and acts before the problem escalates.

Q2: How is it different from a manual circuit breaker?

A: Manual circuit breakers protect the main circuit and need to be reset manually. The KUOYUH 92 automatically operates for internal temperature and manually recovers after cooling. Both are indispensable.

Q3: If the breaker trips often, is there a system problem?

A: Yes. Frequent tripping usually indicates overload or component wear. Inspect the system immediately — don’t repeatedly force reset

Q4: How to choose the right rating?

A: Base it on transformer secondary current and the environment. For example, 4A–12A with 120°C temperature rating.

Q5: Can KUOYUH 92 extend transformer life?

A: Yes. By preventing overheating, it reduces insulation aging and burnout, prolonging lifespan and reliability.

Conclusion: KUOYUH 92 — The Invisible Guardian of Every HVAC System

For HVAC systems, overheating and overload are the most common — yet often overlooked — silent threats. Without timely detection and active protection, the transformer gradually deteriorates under continuous thermal stress.

The KUOYUH 92 Series thermal overload protector is specifically designed to solve this problem. By sensing heat directly at the source, it proactively interrupts power before damage occurs, and automatically resets after recovery — providing precise, continuous, and intelligent protection for the control transformer.

Integrating KUOYUH 92 delivers:

- • Proactive thermal defense that extends transformer lifespan.

- • Reduced maintenance and downtime costs.

- • Improved system reliability and efficiency.

- • Compliance with UL / TUV international safety standards.