PWM vs MPPT Explained: Efficiency, Protection, and DC Circuit Breaker Safety for RVs

How to Choose Between PWM and MPPT? Why DC Circuit Breakers Are the Core of System Safety?

When traveling or living in a recreational vehicle (RV), solar power allows you to stay independent from campground electricity and continue powering essential devices such as refrigerators, lighting, charging ports, and ventilation systems.

However, whether the system can operate reliably, stably, and safely does not depend only on the wattage of the solar panels. It is primarily affected by the type of charge controller (PWM or MPPT) and whether the power distribution and protection design is correct.

This guide explains:

- • The fundamental differences and operating principles of PWM vs. MPPT

- • How different system configurations affect charging efficiency

- • When PWM is sufficient and when MPPT is essential

- • Why DC circuit breakers are a critical safety component in RV solar power systems

- • How to select the correct circuit breaker current rating

- • Why KUOYUH circuit breakers are the preferred choice for RV applications

What Are PWM and MPPT?

| Name | Description | Operating Method | Characteristics |

| PWM | Pulse Width Modulation Charge Controller | Reduces solar panel voltage down to the same voltage as the battery | Low cost, simple structure |

| MPPT | Maximum Power Point Tracking Controller | Tracks the maximum power point of the solar panel and converts excess voltage into charging current | High efficiency, maximizes power utilization |

Regardless of type, both controllers share the same primary purpose → Manage charging, prevent overcharging, and extend battery life.

Core Shared Functions of PWM and MPPT

- • Prevent battery overcharge and over-discharge

- • Prevent reverse current flow to the solar panel at night

- • Support multi-stage intelligent charging (Bulk / Absorption / Float)

- • Compatible with Flooded, AGM, Gel, and LiFePO₄ lithium batteries

Both are battery managers—but they differ in charging efficiency and energy utilization.

Key Differences in Operating Principles

(including weather, wiring, and environmental conditions)

PWM: Trades Voltage for Charging Current

PWM controllers force the solar panel voltage down to match the battery voltage. The unused voltage difference is simply lost as heat.

- • Solar panel operating voltage (Vmp): 18V

- • Battery charging voltage: 13.6V

- → ~25% of energy becomes unusable heat

| Condition | PWM Performance |

| Midday, clear skies | Acceptable |

| Cloudy / dusk | Rapid power drop |

| Cold climate | Panel voltage increases, but PWM cannot use the excess |

MPPT: Actively Tracks Maximum Power Output

MPPT controllers continuously seek the maximum power point (Vmp × Imp) and convert excess panel voltage into usable charging current. Efficiency typically increases by 15%–35%, sometimes more.

| Condition | Reason MPPT Performs Better |

| Low temperature | Solar panel voltage rises → MPPT converts into more current |

| Variable sunlight | MPPT adjusts dynamically |

| Long wiring distance | Higher input voltage reduces I²R wiring loss |

For lithium RV power systems → MPPT is strongly recommended.

Solar Panel Configuration & Battery Compatibility

| Item | PWM Recommendation | MPPT Recommendation | Explanation |

| Panel wiring | Parallel | Series | MPPT benefits from higher voltage to reduce losses |

| Battery type | Lead-acid systems | LiFePO₄ ideal match | Lithium voltage curve suits MPPT |

| Wiring length | Should be short | Can significantly reduce line loss | Useful when solar is mounted far from the battery |

If your RV uses lithium batteries → MPPT is nearly essential.

Cost and Usage Scenario Comparison

| V Usage Scenario | Recommended Controller | Reason |

| Basic loads (lights, USB charging) | PWM | Low cost, simple setup |

| Long-running loads (fridge, pumps, fans) | MPPT | Stable output under variable sunlight |

| Using inverter (cookers, hair dryer, induction stove) | MPPT Required | igher energy efficiency and faster battery recharge |

The Role of DC Circuit Breakers in Solar Systems

Not an accessory—but the core safety component.

RV solar systems use DC power, and DC arcs are long and difficult to extinguish.

Without proper protection, overcurrent can cause:

- • Overheated wires → melted insulation

- • Burned terminals → poor electrical contact

- • In severe cases → electrical fire

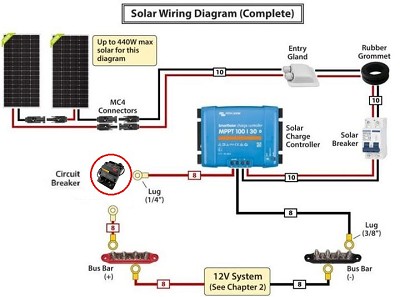

Standard Protection Topology

Solar Panel → (DC Circuit Breaker) → PWM / MPPT → (DC Circuit Breaker) → Battery → Load / Inverter

| Breaker Position | Protection Purpose |

| PV Side Breaker | Prevent controller damage from panel faults or short circuits |

| Battery Side Breaker | Prevent battery reverse discharge from destroying the controller |

In other words, circuit breakers don’t just protect devices — they protect the entire vehicle.

How to Select the Correct Circuit Breaker Rating?

Circuit Breaker Rating = Maximum System Charging Current × 1.25 to 1.4

Example::

- • MPPT maximum output current = 35A

- → Recommended breaker size = 40A–50A

If the system includes an inverter or motor loads → Use 1.4–1.6X.

| Model | Recommended Use |

| 16 Series | Standard MPPT/PWM input & output overcurrent protection |

| AR Series | Off-road, vibration, marine, or humid environments |

| 88 / 98 Series | System main power cutoff before inverter |

Want to know more about KUOYUH circuit breaker applications? Related Reading:

- • 98 / 88 Series →Solar Inverter Circuit Breakers: Protect Your System with MPPT & DC Solutions | KUOYUH

- • AR Series →Protect What Drives You: KUOYUH AR Series Circuit Breakers

Actual Installation Diagram of the Circuit Breaker

This image shows an MPPT charge controller paired with a KUOYUH 16 Series DC circuit breaker (installed on the PV input side for protection).

- • The solar panel input is routed through the KUOYUH 16 Series DC circuit breaker before entering the MPPT.

- • The wiring uses crimped ring terminals with heat-shrink insulation for secure and reliable electrical contact.

- • All cables are clearly labeled (PV / BAT) to ensure easy identification and simplify future maintenance.

Key Point:

This wiring approach prevents excess current from damaging the MPPT input in the event of a solar panel fault or short circuit.

This photo shows a complete power distribution system inside an RV, featuring the KUOYUH 16-8F Series DC circuit breakers.

The focus is not on the solar panels, but rather on how the battery bank, DC-DC charger, inverter, busbars, and protection devices (fuses/circuit breakers) work together as a coordinated system.

Power Flow Overview

Vehicle Alternator

→ DC-DC Battery Charger (stabilizes and limits charging current)

→ Lithium Battery Bank (core energy storage)

→ Distributed to:

- DC loads (lighting, compressor fridge, USB charging, etc.)

- Inverter (Victron MultiPlus) → converts DC to AC household power (outlets, heating appliances, etc.)

Why are Circuit Breakers Essential in This System?

In an RV electrical setup, electrical energy may come from multiple sources:

- • Vehicle alternator

- • Solar charge controller (MPPT)

- • Shore power/campground AC hookup

All of these ultimately feed into the same battery bank.

This means:

- • Wiring and terminals may carry more current than a single source alone

- • Any device failure (short circuit / backfeed / overload) can cause overheated wires, melted insulation, or even fire

- • Lithium batteries can release very high current instantly — without proper protection, the risk is significantly higher

Key Safety Design Features Visible in the Photo

You can see that every major power path has a dedicated DC circuit breaker, such as:

- • Input and output of the DC-DC charger

- • The battery positive line feeds the inverter

- • Battery connection to the DC load distribution bus

The purpose of using KUOYUH DC circuit breakers at these critical points is:

| Function | Description |

| Overload Protection | Prevents wires from overheating due to excessive current |

| Short-Circuit Protection | Immediately disconnects power when a short occurs |

| Backfeed Prevention | Stops current from flowing back from the battery into connected devices |

| Maintenance Convenience | Can be used as a manual power switch for safe system isolation |

Conclusion

| User Requirement | Recommended Controller | Notes |

| Low-power, simple setup | PWM | Sufficient for basic needs |

| Lithium system, inverter usage, and long-distance travel | MPPT | Higher efficiency and faster recharge |

No matter which controller you choose:

DC circuit breakers are not optional. They are essential safety components that protect your equipment, your RV, and your trip.

Correct protection design =Longer battery life + safer wiring + more reliable system + worry-free travel.